On Artisans and Switches

On Artisans and Switches: A Take in (Hopefully) One Piece

Author: ThereminGoat

Published: May 8, 2023 Entry for Artisan Collector Writing Contest 2022

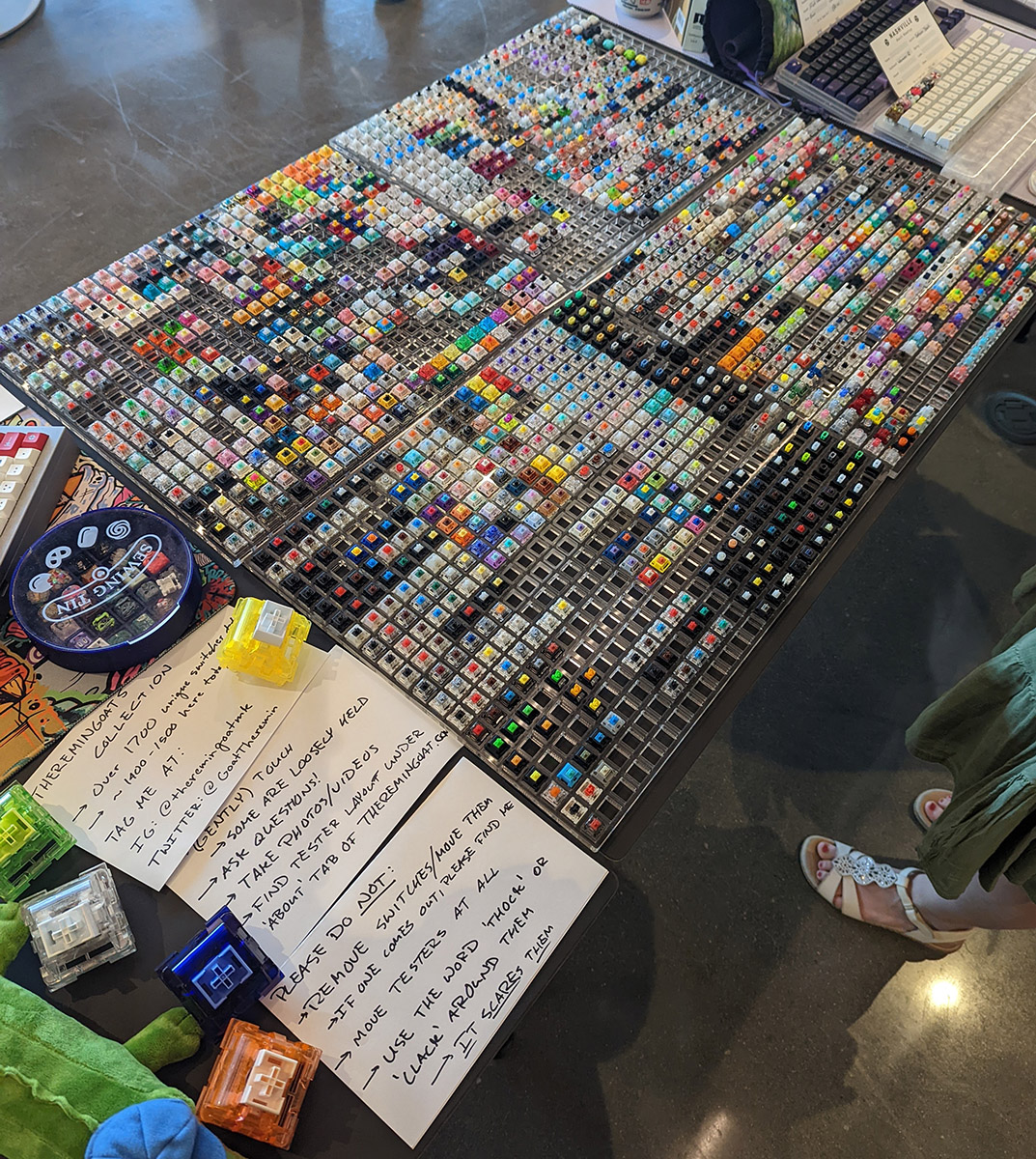

Look, I already collect switches so there is no way I could ever possibly afford to take up an artisan keycap collection on top of all of that. Surely I can simply appreciate them from a distance. Every now and then there will likely be interesting sculpts, colorways, or even themed releases of keycaps that strike me as interesting and I might briefly check out the raffle forms to s- Wait, these are how damn much for a single keycap?

You know what, screw this entirely. From this point on, I’ll only take artisans from completely free giveaways or from some of the prize pools at meetups that I attend. The only exception will be those super rare, one in a million exceptions that just check all of the boxes of my ideal artisans. Oh, and it will almost certainly be a one and done raffle entry, no questions about it.

After having my first big raffle win in the form of my KWK Skeletor Mummy III, it was pretty hard to refute that I had fallen into the trap that many people who hang around the keyboard scene long enough fall into. What was once derision at “insane” prices for artisans since ‘I could just do that myself’ had morphed rather rapidly into an appreciation of the handmade craftsmanship that (most) artisan keycaps have. That is not to say, though, that that transformation in opinion was complete the day that that first Mummy hit my mailbox.

As I have dug deeper into the artisan scene over the course of the past year or so, I’ve learned so much in a similar fashion to how I first started out learning about switches. Many of my spare moments were spent flipping through old Geekhack pages, scrolling every single entry on the Hatchery, and asking anyone who would give me the time-of-day questions about artisan history. I’ve found that my fascination with the history of the artisan scene, the tales and stories of its makers, and the inevitable associated fiascos of a keyboard-related hobby has only continued to grow proportionally with the number of questions I think up about them. While I would like to think that I have made many friends within the artisan space over the span of my budding interest, there have been a particular pair of individuals with whom I feel I owe a special thanks to – JQ and RMendis.

To those of you who are almost certainly reading this article on artisancollector.com, these two names are pretty old news to you by now. While they may just be part of it all to those more experienced within artisans, to an outsider like me they have stood as pretty strong encyclopedias of artisan keycap knowledge. Encyclopedias which I can routinely ping with questions well into the late-night hours. As I’ve grown fond of the small space that I feel that I’ve carved out within the active artisan collecting community out there, my conversations with these two, and especially JQ, have only grown more deep.

Interestingly, though, as I’ve begun to ask more in-depth questions about the histories of various makers and keycaps, JQ has somewhat turned the tables on me and begun to push back with a much smaller amount of questions with respect to my expertise in switches. Tying this into our conversations about artisans, it’s not all that surprising that at some point the conversations became intertwined, discussing the relationships between artisans and switches new and old alike. After all, if we actually used artisan keycaps for their intended purposes, the only thing that they would touch would be switches...

Well, in ‘rubber hits the road’ type fashion, I couldn’t help but see an opportunity here to write a way too long article about what actually happens when we flex our artisan keycaps along the numrow of our daily drivers. In the extensive amount of hours that I’ve put up to this task, I’ve boiled down the results of this simple action of mounting a keycap to one of two possibilities. These are illustrated as follows for those of you who are more picture minded, like me:

While seemingly not as much of an issue today as it was previously, stem cracking has certainly been a historical issue with various types of keycaps all across the community. Even as far back as when I first joined the hobby around 2018, I vaguely recalled having seen the occasional post on r/mechanicalkeyboards of people losing a beloved ‘F’ key from their favorite GMK set to a stem-cracking switch. Interestingly, as I’ve dug further into the artisan keycap scene, the vividness of my memories surrounding these posts have only increased. What is more or less old news and something that only happens to a rare few people every now and then is still something that routinely haunts the thoughts of artisan collectors – and especially those who feel compelled to mount their end game resin onto boards. Perhaps it isn’t entirely unsubstantiated when you still fairly frequently see the ghosts of caps such as a singleshot, light grey Mummy floating through mechmarket channels with a cracked stem.

Wanting to dig in a bit to see if this stem cracking monster in the closet was as real as all of those collectors out there claim it was, I took to doing what I do best and went researching into the depths of switch history. Surprisingly, rather than pulling out a monster of a tale that would stretch pages on end, I simply found a small set of posts which pretty clearly outlined the panic at the time. This big “stem cracking epidemic” of 2018 which still echos in the minds of keycap collectors to this day was pretty squarely summarized in a pair of reddit posts by Novelkeys and Kailh. (Editor's Note: Kalih also posted on Deskthority.) In these posts, Mike of NK shared that the Box line of switches had an East and West direction keycap mount post width of around 1.32 mm (+/- 0.02 mm tolerance) which was actually rather substantially greater than their original specifications at 1.30 mm of width. The reason for this was a simple request back when Box switches were first introduced, in which the largest (and at the time only) vendor/manufacturer using the Box switches requested this specification change. After halting all Box switch sales and striking an agreement with Kailh to change the specifications back to their original value, the post ends rather plain and simply there. That’s it. That was the entirety of the stem cracking epidemic as it happened live.

With it not being all that much of an issue in the first place, after this specification change and notification by Novelkeys the bulk of the cracking panic subsided and has yet to pick up since. Even though a large part of this appears to be isolated to a relatively narrow range of switches produced back in the day, the rise of artisan collectors using boxes or display trays rather than mounting their collections onto keyboards certainly has helped further decrease this issue as well. But I’ll admit that I wasn’t entirely satisfied with the fact that this was it. Here I was, planning out a mashup article for the ages between artisan keycaps and switches and instead of pages upon pages I get something that Google cleared up for me in 0.11 seconds. Upon reading over the response from Mike of Novelkeys once more before declaring defeat and going back to the drawing board, one switch mentioned in particular in this response stood out to me – Novelias.

Given that I assume the majority of readers on this website aren’t as deeply in love with switches as I am, let me share with you why Novelias are particularly interesting even if they have been lost to the switch sands of time. These limited time, pink colored Box switches, which were designed to go with the original run of GMK Olivia keycap sets, first went on sale on June 30th - exactly one month before Novelkeys’ update about stem cracking Box switches. Priced at $6.00 per pack of 10 switches, I distinctly remember these switches as they were the first custom switch groupbuy which I actively took part in as acollector. However, aside demarcating the start of my clear and present addiction, these also are historically interesting as they are among the very first custom colored, specially designed switches of the modern era. That’s right: Novelias predate every switch you have come to know and love now including all of your Gateron Inks, the entire history of JWK and Tecsee, and every last one of them. And yet, we haven’t seen a rise in keycaps cracking any time except for just before these switches kicked everything off.

Since June of 2018 there have been hundreds of new switches designed and made by dozens of brand-new manufacturers with a list that keeps on growing even as of the time of writing this article. No longer held up by the big hitting brands of Cherry, Kailh, and Gateron, new manufacturers took full claim to a community enamored with customizable switches, new designs, and enough colors to make an artisan collector jealous. Interestingly, though, we haven’t seen a rise in keycaps, artisan or otherwise, cracking under the stress of all of these new releases. Please do not think that this is strange purely as a function of switches increasing though – artisan makers have increased in number and volume drastically over the past couple of years alongside this. Even though there are still some newer makers out there doing their thing from scratch, the rise of standardized mold making boxes such as the Synth line from HWS has ensured that the vast majority of these newer, smaller makers are probably casting with butts fitted to the original Cherry specifications – after all, this is what the Synths were designed around. So let’s take a step back and look at where that leaves us:

We have hundreds of new switches being paired with an increased number of artisan keycaps which are likely less variable in their mounting tightness than at any point in artisan history and yet there hasn’t been an increase in keycap cracking.

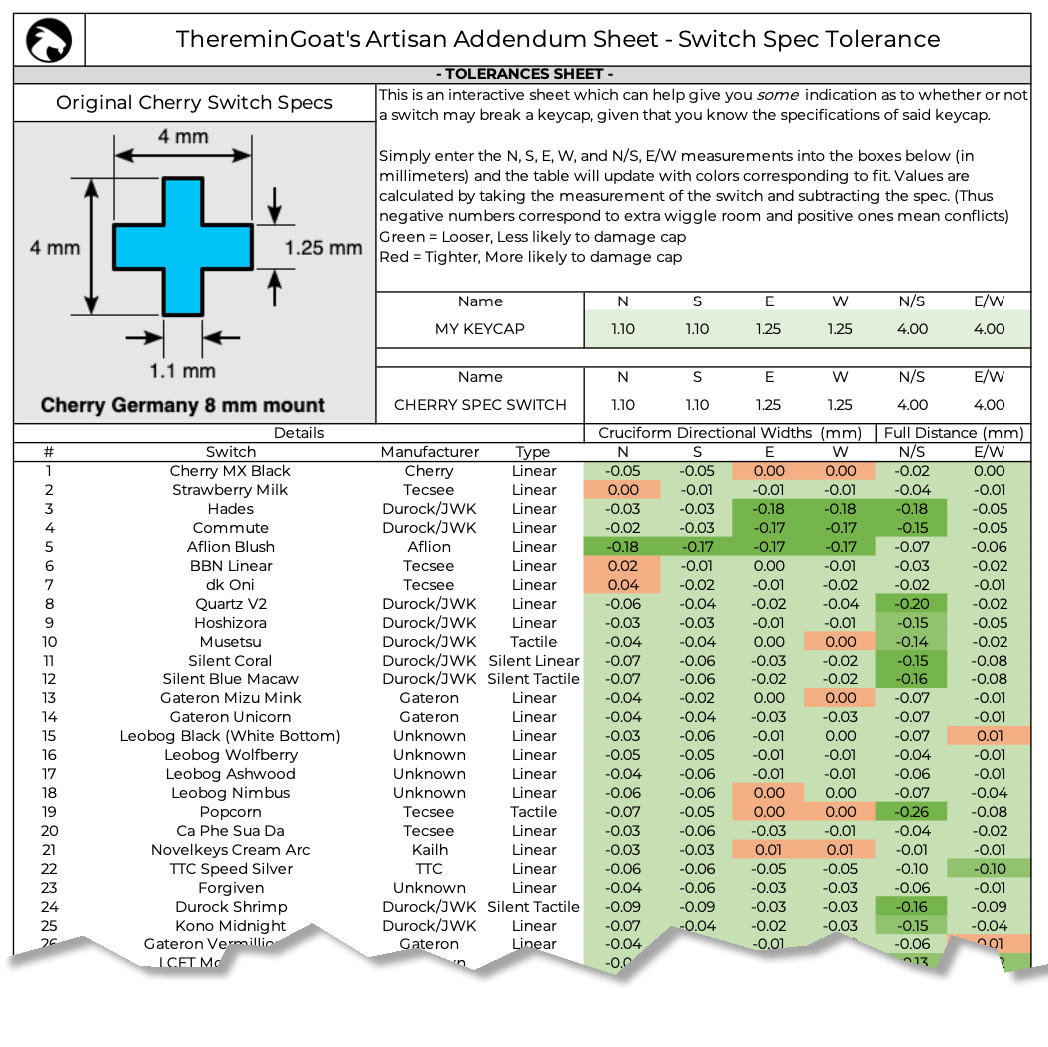

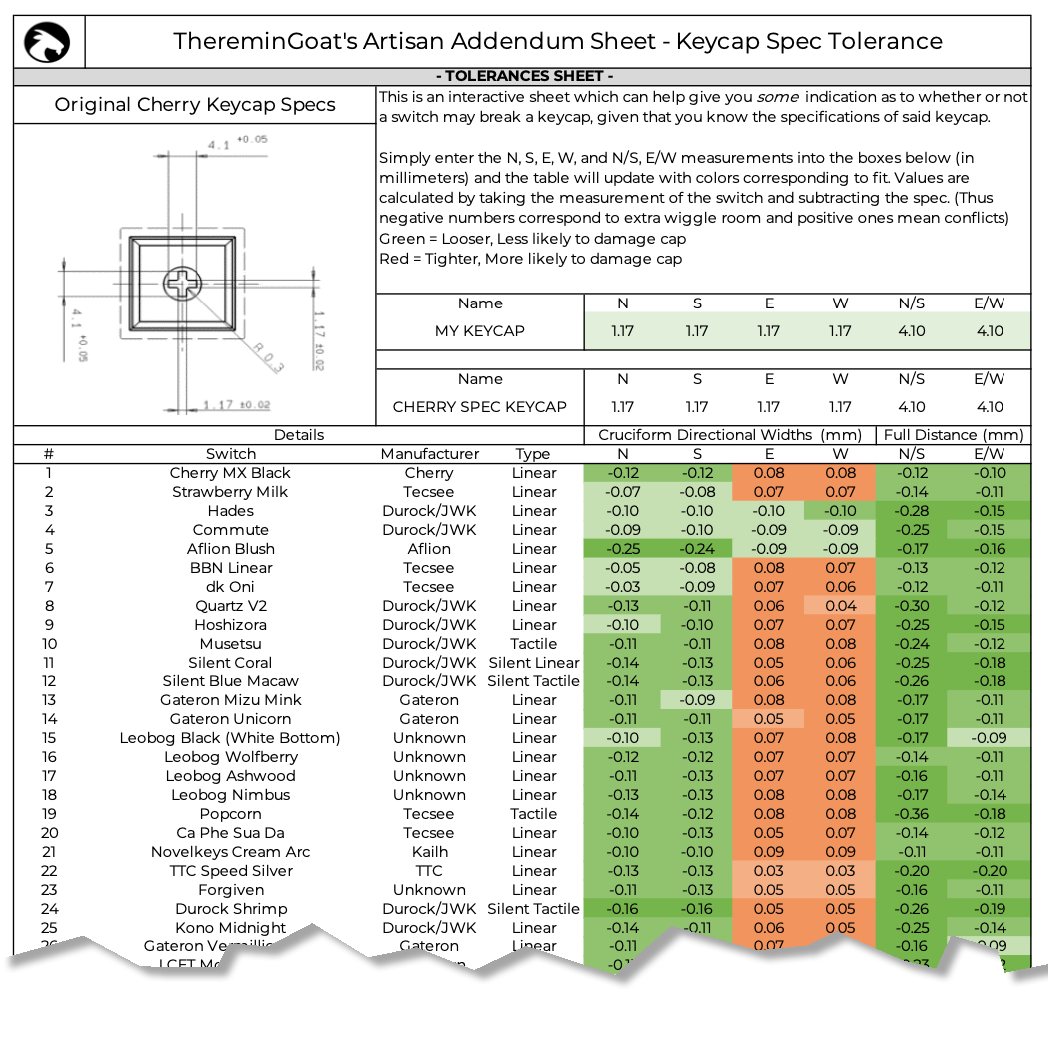

With this seeming contradiction in mind, I did what any good scientist does and went out and made some measurements to try and see if I could figure out why this was the case. Taking six different measurements of keycap mounting portion of the stems of some of the switches that I had lying around my house, I was able to create the first real set of data on keycap mount measurements of modern switches. Dubbing this the ‘Artisan Addendum’, as it is both alliterative and serves as an extension of my current Switch Measurement Sheet project, I have measured 200 different switch stems as of the debut of this article with proper replications and repetitions of each measurement such that each value you see in the database is the average of 9 different measurements. Either before moving into the following paragraphs or afterwards, I highly encourage you to go check out the Artisan Addendum Excel Worksheet. (I plan to update this regularly as part of my content in the future and it will not be going anywhere!) Editor's Note: To see the box charts, you need to download the worksheet and open in Excel. For your convenience, I have provided the two main measurement sheets as PDFs below.

Taking the original Cherry keycap specifications into consideration as I set up these charts and this data sheet, I measured each of the six aforementioned measurements for 17 different manufacturers including ones you all know and love like Cherry and Gateron as well as newcomers to the game such as Mengmoda, Aflion, and Haimu.

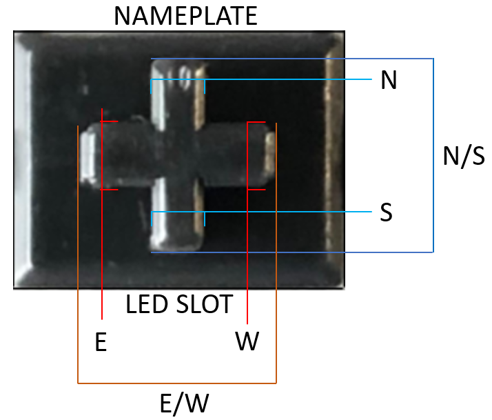

Diagram of the six keycap stem mount measurements made in the Artisan Addendum.

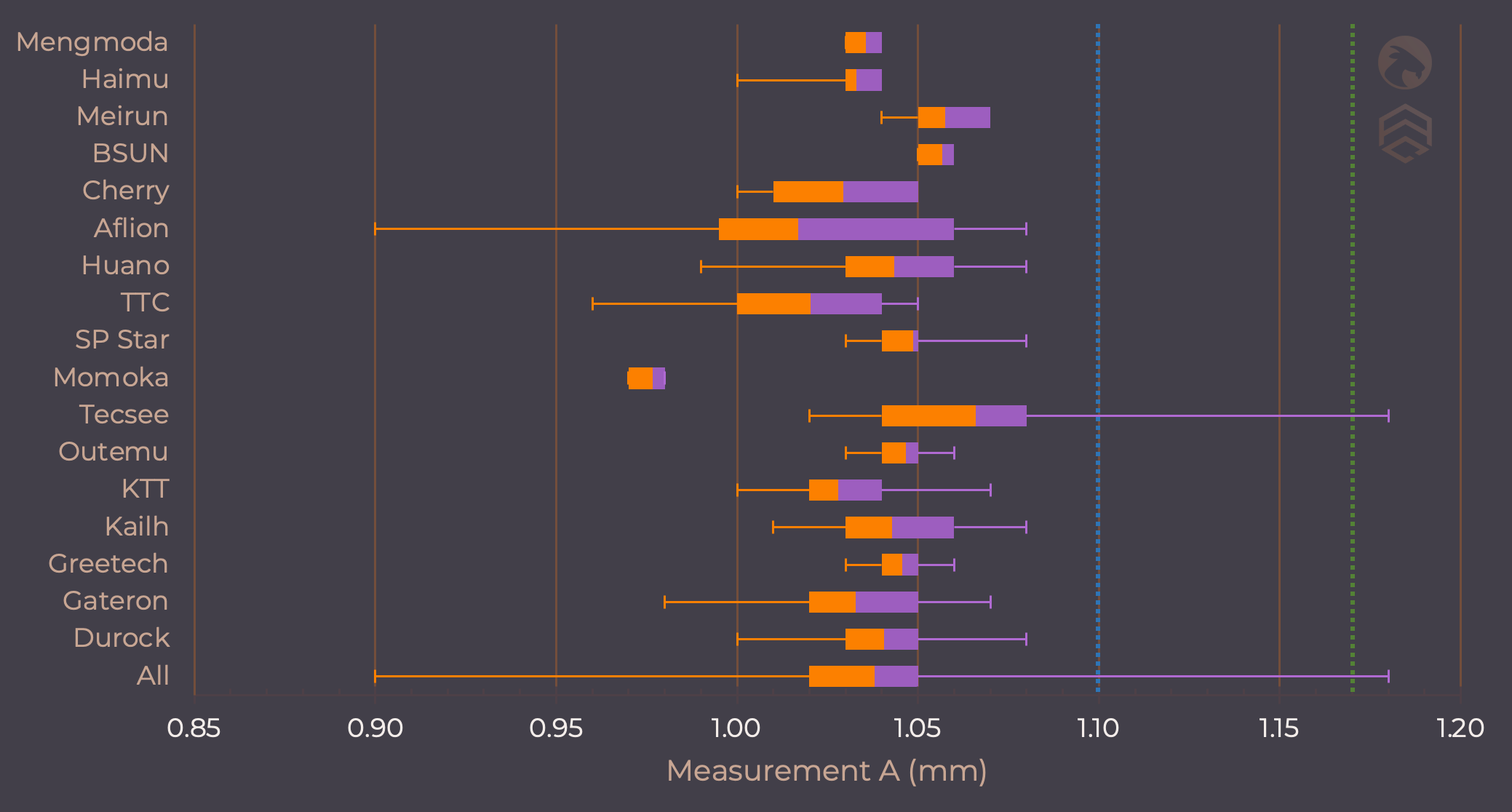

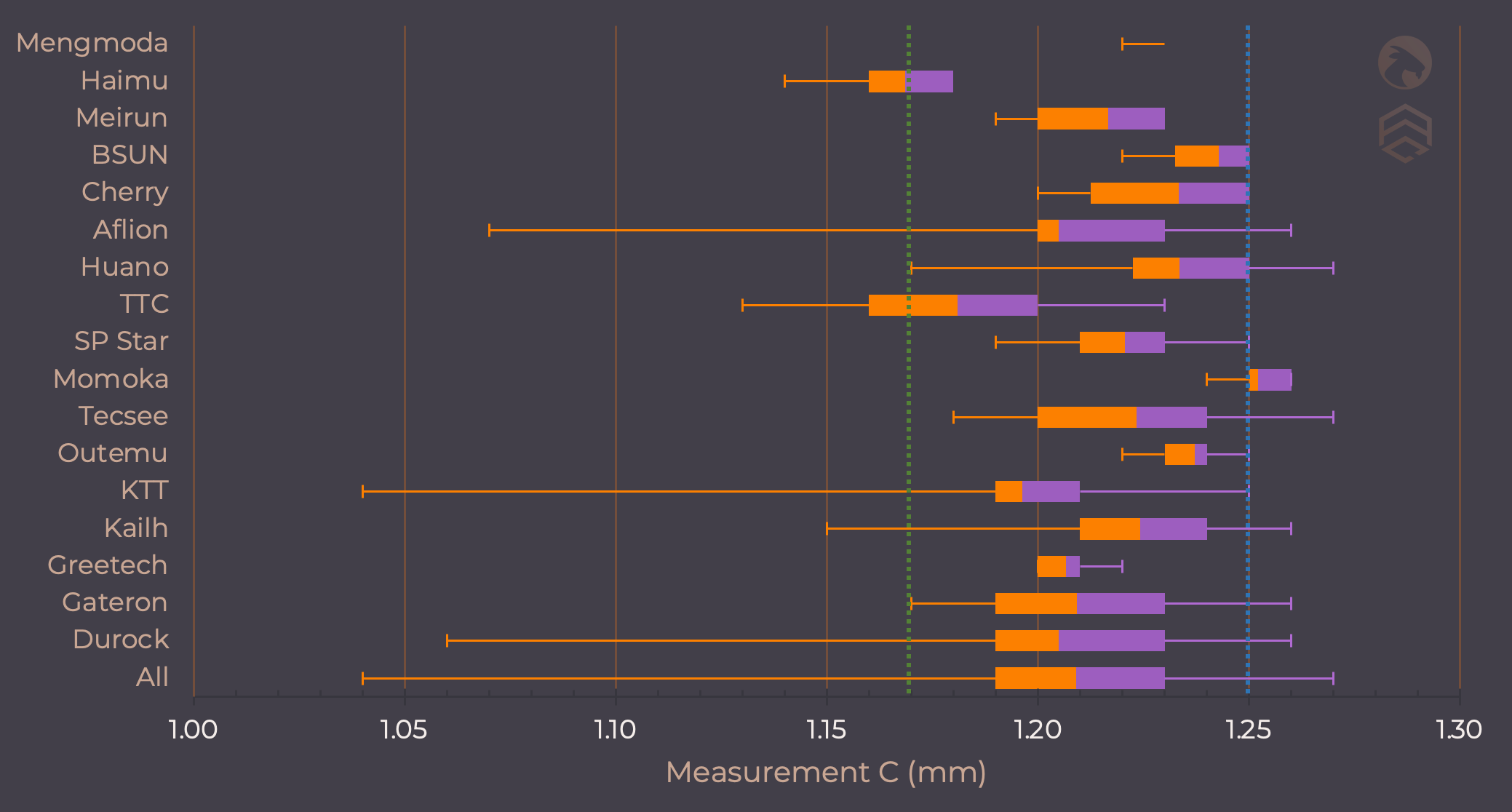

Utilizing box and whisker style plots as a way to compare the total spread of measurements on a brand-by-brand basis, I first wanted to look to the widths of the North and South side keycap stem mounting posts. With the Cherry specifications for keycaps clearly marked with a green line (black line in the Excel worksheet), it’s easy enough to see in Charts 1 and 2 below that the vast majority of switches fall underneath the keycap specification at 1.17 mm in total width. In fact, of the 200 switches that were measured, only a small handful came anywhere near close to this ‘limiting value’ of sorts and only with respect to the North side measurement widths. Based on these two measurements alone, I guess it really isn’t all that surprising that we haven’t seen many keycaps, artisan or otherwise, crack over the past few years.

Chart 1: North Width Measurements

Box and whisker plot of the width of the North side keycap stem mount by brand.

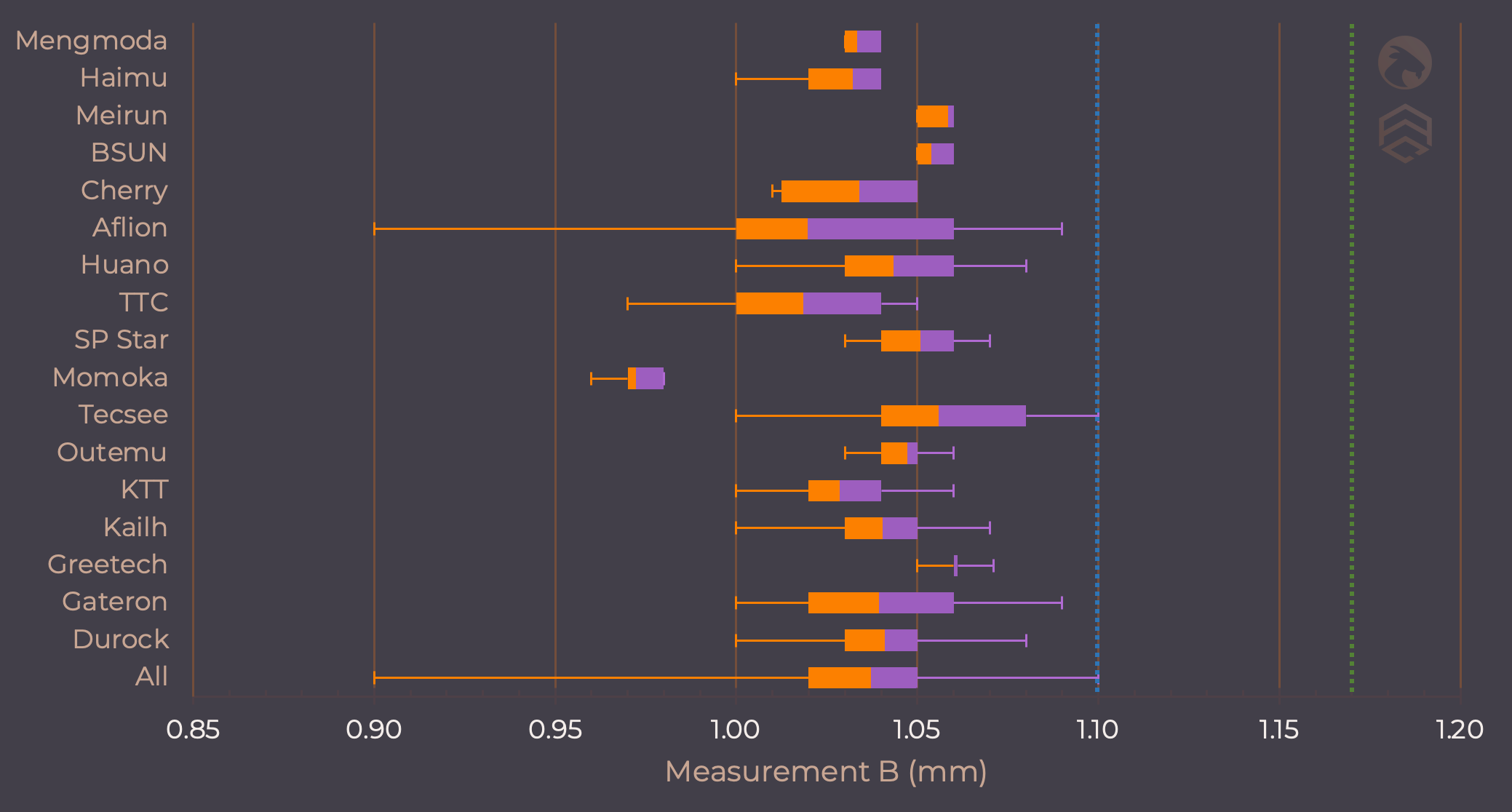

Chart 2: South Width Measurements

Box and whisker plot of the width of the South side keycap stem mount by brand.

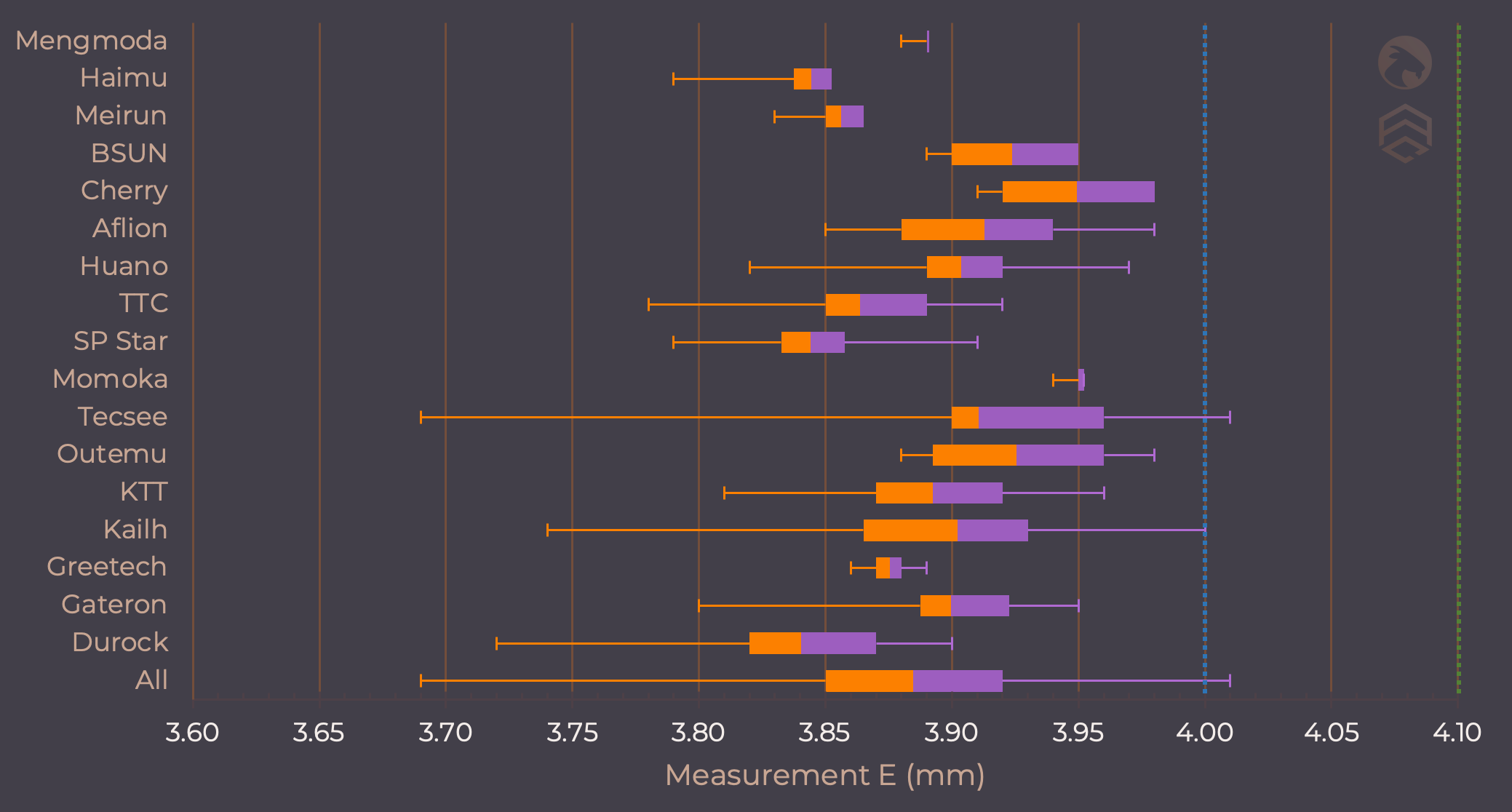

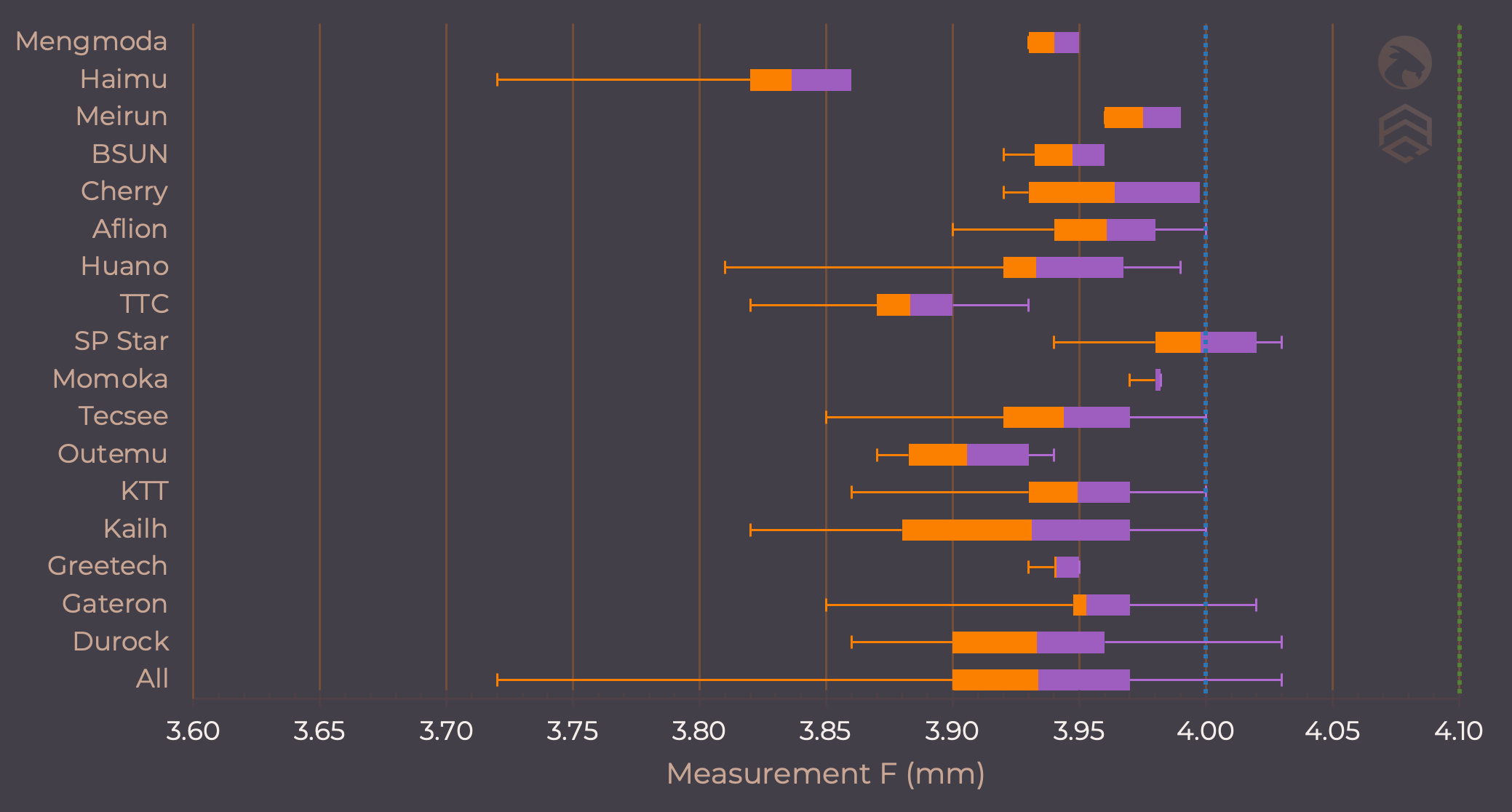

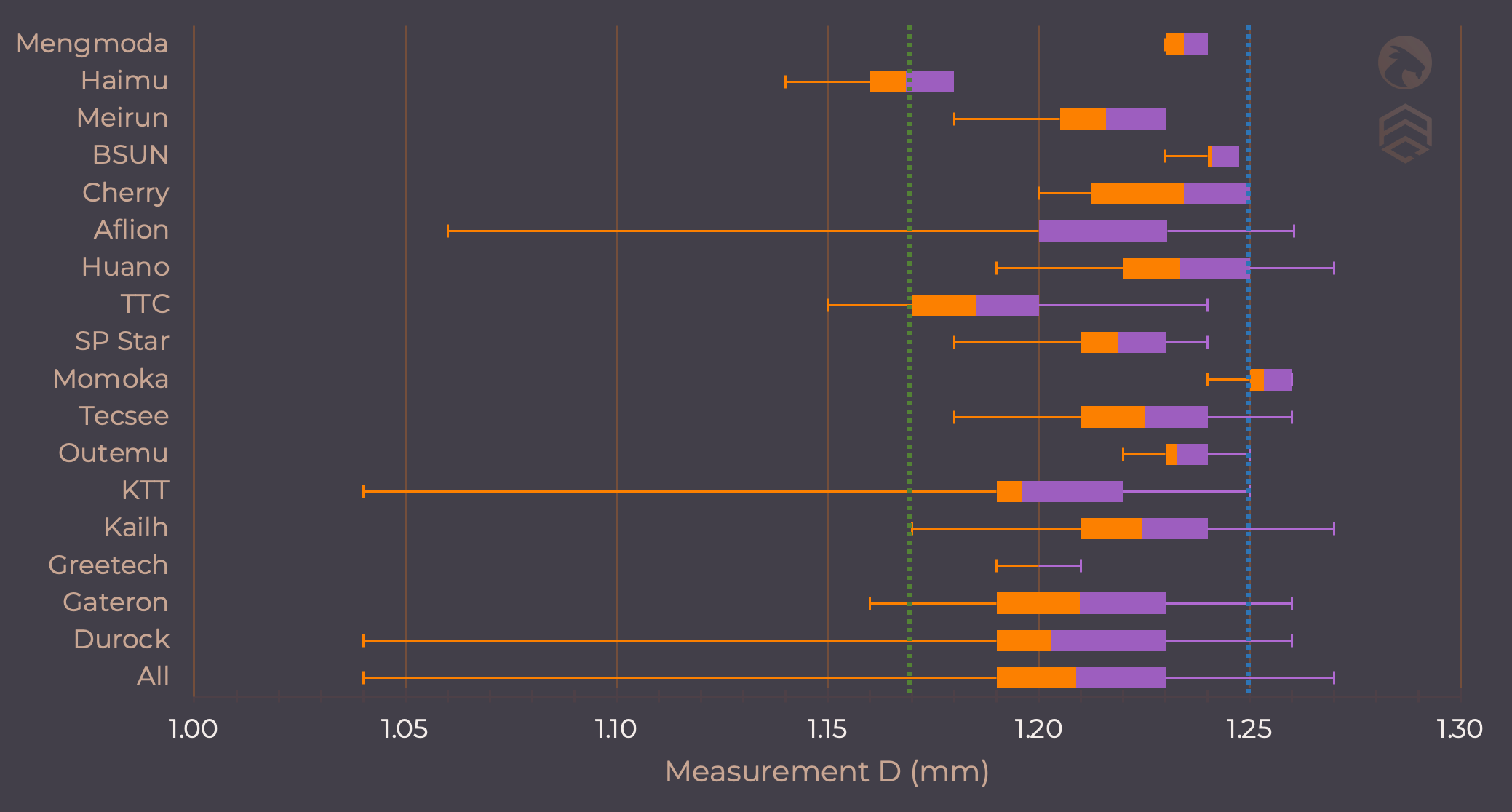

With the North and South side widths clearly not showing any sort of reason to crack, the next logical step for me to look at was the total North to South (N-S) and East to West (E-W) distances that the keycap stem mount span. As per the original Cherry keycap specifications, these 4.10 mm-wide gaps seem to me to be reasonable places where cracking could occur. If perhaps the very centers of the keycap mounting stems were larger or contained a wider spacing, it could easily stretch the N-S and E-W distances in modern switches, which could lead to cracking at the sharp edges of the ‘plus shaped’ keycap hole since that is where the stems are most often the thinnest. Alas, though, every single measurement made on all 200 switches fell well below this specification mark, even with the longest N/S and E/W distances below even 4.05 mm as can be seen below in Charts 3 and 4. Strangely enough, though, looking at these two graphs side by side, it does appear as if the E-W distances on average are fractions of a millimeter longer than that of the N-S directions...

Chart 3: N to S Measurements

Box and whisker plot of the total North to South length of the keycap stem mount by brand.

Chart 4: E to W Measurements

Box and whisker plot of the total North to South length of the keycap stem mount by brand.

Knowing then that something might be up with the East and West keycap stem mount widths, I arrived at my final pair of graphs as can be seen below in Charts 5 and 6. However, unlike seeing measurements well below the specifications of Cherry’s standard keycap specifications all across the board, we are presented with a rather bleak outlook – the vast majority of switches measured have East and West post widths thar are wider than traditional Cherry keycap specs. In fact, of the 200 switches measured, only 10 total ones were with in Cherry’s specifications on these measurements. Of these 10, 5 were manufactured by Durock/JWK, 2 by Haimu, 2 by TTC, 1 by Aflion, and 1 by KTT. As well, unlike that of the N-S and E-W measurements above, these widths both seemingly overshoot this Cherry keycap specification by similar amounts.

Chart 5: East Width Measurements

Box and whisker plot of the width of the East side keycap stem mount by brand.

Chart 6: West Width Measurements

Box and whisker plot of the width of the West side keycap stem mount by brand.

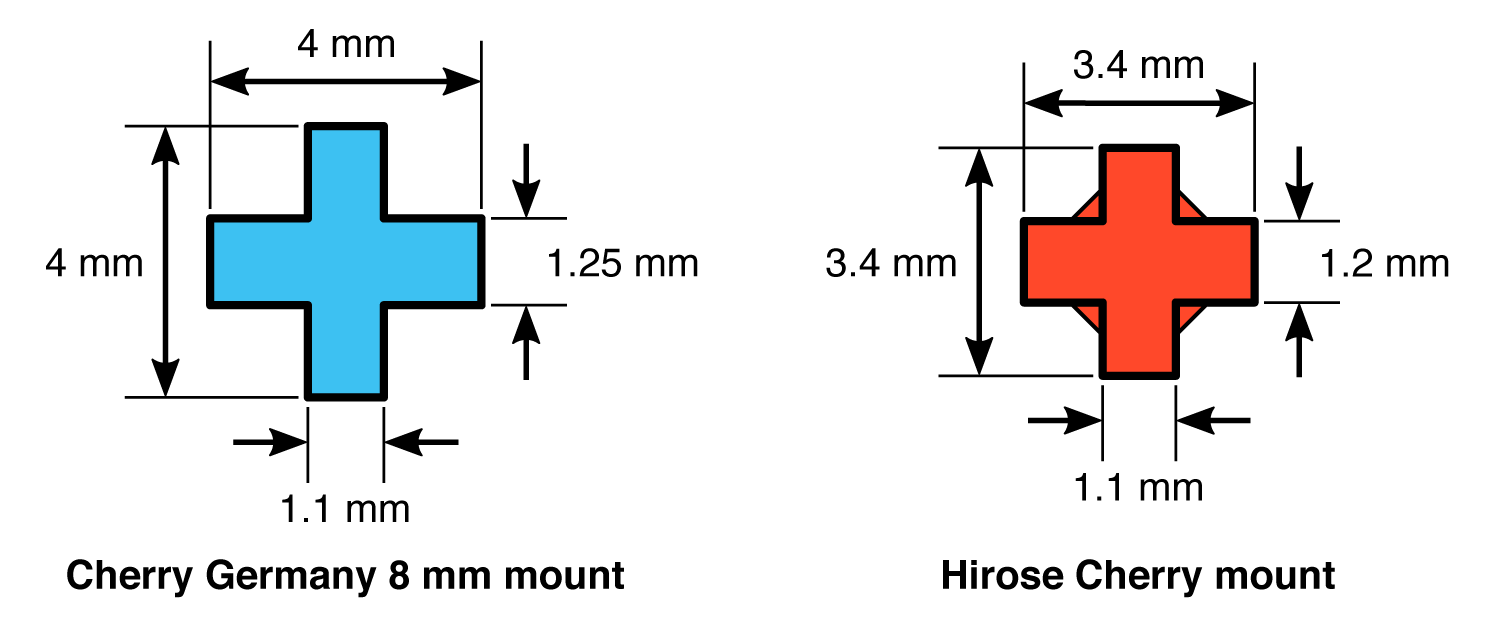

With all of this data laid out before me, I genuinely didn’t feel as if I had only good rationale to explain the trend, or rather lack thereof, that we’ve seen in keycap stem cracking over the past handful of years. I double checked the numbers and even visited Cherry’s own website where I got these keycap specs from multiple times in order to make sure that I wasn’t losing my mind. However, when I sat and thought on this a bit longer, I came to the realization that I may have been considering the wrong set of specifications from the get-go. Upon having conversations with various artisan people specifically about the Synth artisan molds, which were reported to have been made to original Cherry specifications, I realized that the original designers probably didn’t make this to Cherry’s keycap specifications, but rather Cherry’s switch specifications. Surely those couldn’t possibly be different... right?

Ha! Guess again! German Cherry 8 mm mount versus Hirose Cherry mount (Cherry)

As fate would have it, rather than having a perfectly symmetrical cross structure with arms each 1.17 mm wide, the original Cherry MX switch specifications called for the North/South sides to be 1.10 mm wide whereas the East/West sides would be 1.25 mm wide. Interestingly, through conversations found on Geekhack from many years ago, this seeming discrepancy between standard keycap and switch mount specifications was not only discovered but well understood. Rather than classic Cherry being classic Cherry, this mismatch in dimensions is a function of basic physics. Given that there is still residual air trapped inside the gap between the keycap stem and the switch stem when they are connected together, that air has to come out in some fashion upon pressing otherwise there may be issues with the stem not pressing in fully. This air, rather than being trapped permanently, can escape through the narrower North and South stem mounts as they are thinner than Cherry’s original specifications for keycaps. So, by best guesses it’s very likely that the specifications we need to actually be considering are those outlined above on the left-hand side of the "German Cherry 8 mm mount versus Hirose Cherry mount" illustration. (Don’t consider the demon-spawn keycap killers that are Hirose switches...)

Taking this change into consideration, I then remarked the each of the above graphs with a blue vertical line noting the Cherry switch specifications in the same fashion as that of the green line denoting the Cherry keycap specifications (black line in the Excel worksheet). While all of the measurements pertaining to the North and South side mounting points hardly change at all with respect to being over/under this line, we magically see that the vast majority of measured East and West widths are smaller than that of the Cherry switch stem specifications. In fact, of the 200 switches measured, only 8 of these were over the East and/or West width or total E/W distance specifications, with the most common manufacturer being that of SP Star with 3. Comparatively, only 3 total switches were outside of either the North and/or South width specifications, with all 3 belonging to Tecsee specifically. So, all things considered, it’s not all that surprising to think that we aren’t seeing more keycap stems crack as only 4% or so of all switches being made even pose a risk based on this data set here.

With this in mind and taking a step back to look at the old Kailh Box switches which were insinuated as the direct cause of all these fears, it actually makes significantly more sense in retrospect. In the Novelkeys announcement which launched me down this rabbit hole, it was stated that the original Kailh Box switches had measured in at the time with stem post widths between 1.28 and 1.30 mm respectively – a larger discrepancy from traditional Cherry switch stem specifications than literally 99.5% of all the switches I analyzed here for this article. Noting as well that Novelkeys had stated there would soon be updated molds from Kailh to prevent further issues, its further interesting to point out that the Kailh Box switches that I measured for this article that I collected around 2020 only measured in around 1.23 mm in East and West stem width measurements. While I entirely don’t blame people for this continued fear into 2023, it would seem to appear that the long-standing community wisdom regarding never mounting keycaps of any kind on Kailh Box switches might actually be unfounded.

Coming to a close of this wall of data and overly wordy sentences, I can say that I honestly am rather impressed that the data has brought out as definitive results as it has. Narrowly avoiding the disaster that this article would have been if I had stuck with only considering Cherry’s keycap specifications and not their switch ones, we have clear answers as to why we’ve seen a drop off in stem cracking of both artisan and GMK keycaps since the Cracking Apocalypse of 2018(TM). Does this mean that I am advocating for everyone to go out and mount their precious 1/1 raffle wins onto whatever switches they want? Absolutely not. Perhaps keeping artisans of such value in boxes (or Ziploc bags) is the correct answer for total certainly and peace of mind. However, I am advocating that perhaps it is time for the community to toss out this old wisdom about Kailh Box switches and to have a little more peace of mind with respect to using their artisan keycaps for their intended purpose.

In between now and the next time in which I post an artisan-themed extravaganza of an article, know that I’ll be continuing to expand the Artisan Addendum Excel Worksheet. while constantly looking to see if any new exciting or revelatory trends pop out of the measurements enough. In addition to just having the graphs outlined here in this article available, I also have native Excel-driven suites where you can enter measurements for your favorite artisans to get real time comparisons against switch measurements I have collected in order to help make your decisions on your next keyboard build. While I think that by the numbers you’ll likely be safe with nearly any switch nowadays, the resource will always be there for people to check out as many times as they want. Kind of in the same way as how we all keep refreshing our inboxes after getting the ping on Discord that invoices are out.

First of all, I would like to thank ThereminGoat for this excellent article and analysis. Concerns about artisan and keycap stem cracking have always persisted, and this work shines some much needed light on the topic. Theremin also maintains a much larger database of stem measurements, along with a massive repository of switch reviews, so make sure to head over to his Web site and check it out!

Note #1: This data clearly shows that recent Kalih switches are within standard Cherry tolerance specification and comparable to other popular switch manufacturers. However, in full transparency, I did want to point out that there are anecdotal posts on reddit of Kalih switches cracking stems after the new molds. I would surmise that this is not widespread, but still want to mention it as a point of caution. Note that even with the new molds, some Kalih switches still have the characteristic "nubbs" at the ends of the East and West crucifix (see image below). I am not sure why this design persists, which is different than the uniform width of other mx switch crucifix designs, and whether these nubbs put unequal pressure on keycap stems over time.

Note #2: Regardless of whether switch manufacturing inconsistencies are culprits for stem cracking or not, keep in mind that artisans are typically cast by hand in small batches and much more susceptible to deviation from keycap stem recommended tolerance specifications. I have personally experienced stem cracks across a wide variety and age of artisans and switches (Cherry Ergo Clears, I'm looking at you). Please exercise caution when mounting artisans, especially older ones whose resin characteristics may have changed depending on environmental exposure. Some makers recommend running the stem under hot water before mounting, which is worth considering if you run across a tight fit.